Production

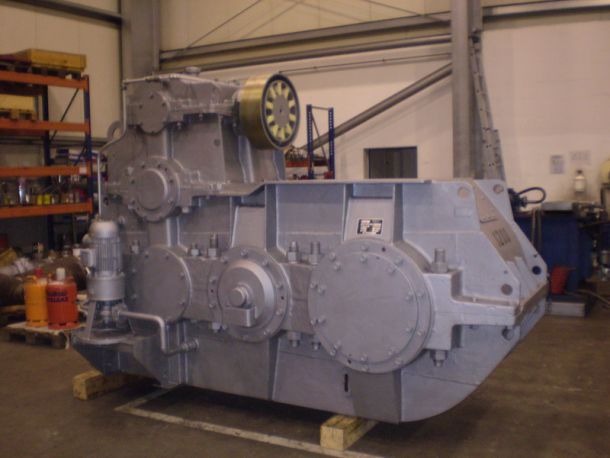

Repair of gearboxes

Production and assembly of components

Production of individual parts

Machinery- &

Performance specification

1.1 Milling machine FIL FRESATRICI, FBM 600

– Table surface: 6500 x 1500 mm

– Travel: x-axis 6000 mm

y-axis 1000 mm

z-axis 1500 mm

Control: Heidenhain digital control TNC 426M

1.2 Universal milling center “Deckel-MAHO DMU 125P”

– Table surface: 1250 x 1000 mm

– Travel: x-axis 1250 mm

y-axis 880 mm

z-axis 800 mm

Control: Heidenhain 3D contouring control TNC 430

1.3 Vertical machining center “Deckel-MAHO DMC 63V

– Table surface: 800 x 500 mm

– Travel: x-axis 630 mm

y-axis 500 mm

z-axis 500 mm

Control: Heidenhain 3D contouring control TNC 430

2.1 CNC lathe “OKUMA-LB400M-C 1250 “

– Rotation over bed: 620 mm

– Rotation over face guide: 420 mm

– Face path: 300 mm

– Longitudinal travel: 1250 mm

– Control: CNC control OKUMA =SP U100L

2.2 Carousel lathe “OKUMA-V 100 “

– Swing diameter: 1250 mm

– Turning range up to Ø 1000 mm and length 1000 mm

– Travel x-axis 565 mm

– Travel z-axis 890 mm

– Control: CNC control OKUMA =SP U100L

2.3 Universal center lathe ” SUS 80H/2750 mm – TOS Celakovice “

– Rotation over bed: 840 mm

– Rotation over support: 530 mm

– Center distance 2750 mm

2.4 Universal center lathe “SUA 100 Numeric – TOS”

– Turning diameter over bed: 1050 mm

– Turning diameter over support: 720 mm

– Center distance 3000 mm

3.1 Column drilling machine: VS 32 B

– Largest drilling diameter 32 mm

4.1 Bandsaw: HBS 321G with micro cooling spray system

– largest saw diameter 320 mm

5.1 MAG welding workstation for steel

6.1 Assembly workstation 18 x 20 m

7.1 Overhead crane “ABUS” 20 t / 10 t

7.2 “ABUS” column-mounted slewing crane 5 t

7.3 “Vetter” pillar-mounted slewing crane 2.5 t

7.4 “Vetter” pillar-mounted slewing crane 0.5 t

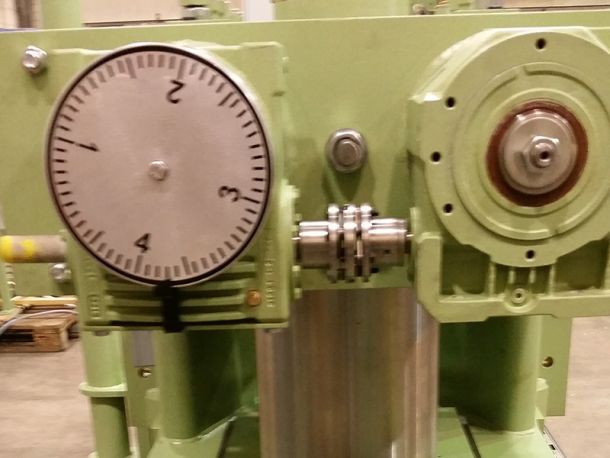

3D coordinate measuring machine type Coord 3 Hera Nomos

Measuring range:

– x-axis: 1200 mm

– y-axis: 1000 mm

– z-axis: 850 mm